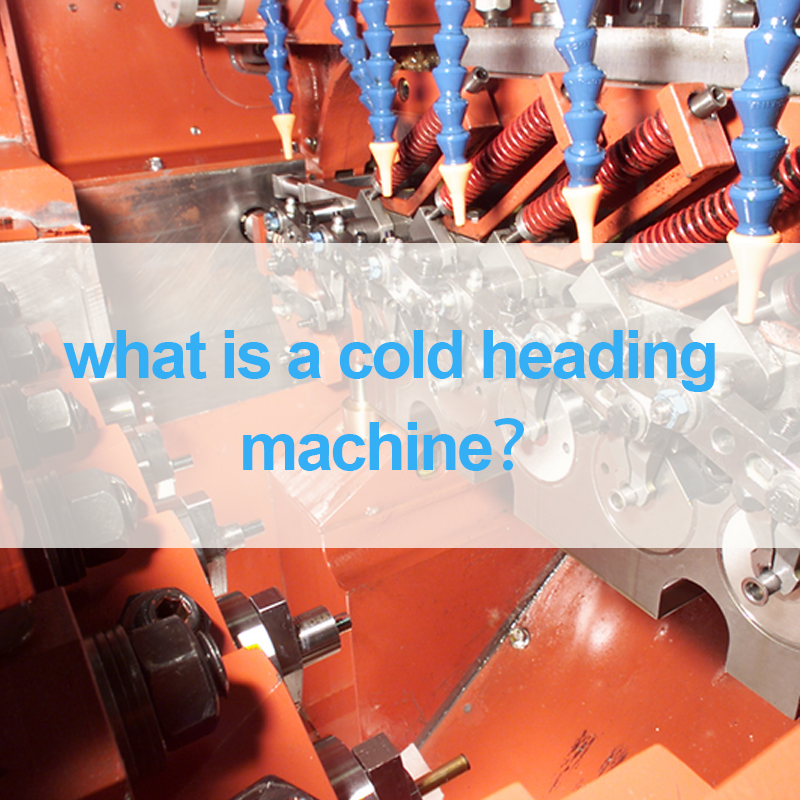

Cold heading machine is a kind of mechanical equipment used to manufacture metal parts, mainly through the cold heading process to mold parts. It is mainly divided into four parts: machine body, transmission system, crankshaft slide, feeding and mold.

The body is the basic part of the cold heading machine, which is used to support and install other parts. It is usually strong and rigid enough to ensure the stability of the machine during the cold heading process.

The transmission system is responsible for transmitting power to the various working parts. It usually includes components such as the motor, pulleys and gears. The motor provides the power, and through the transmission of pulleys and gears, the power is distributed to the crankshaft, slider and other parts of the cold heading machine according to a certain speed and torque requirement, so that they can work according to the predetermined movement law.

The crankshaft and slider are the core moving parts of the cold heading machine. The crankshaft makes rotary motion under the drive of transmission system, and the rotary motion is converted into the reciprocating linear motion of the slider through the connecting rod. The movement speed and stroke of the slider can be adjusted according to different cold heading process requirements. In the process of cold heading, the slider drives the mold to upset the metal blank.

The main function of the feeding part is to send the metal blank to the mold cavity according to a certain rhythm and position. This part usually includes hopper, feeding wheel, feeding rail and other parts. The hopper is used to store the metal blanks and the feed wheel takes the blanks out of the hopper by rotating and transports them to the mold position along the feed rail.

The die system is the key part of the cold heading machine to realize the forming of parts. It includes various kinds of molds such as punch molds, concave molds and so on. Different shapes and sizes of parts require the use of corresponding molds.