Product Trends – Application of High-Performance and Lightweight Materials

To adapt to the specific working conditions of intelligent robots and drones, fasteners are evolving towards high performance and lightweight.

Material innovation is key. Traditional steel fasteners offer high strength but are heavy. Drones count every gram for weight reduction, making fasteners from titanium alloys, aluminum alloys, and composite materials increasingly common. They significantly reduce airframe weight while ensuring sufficient strength, extending flight time. In robotics, especially collaborative robots, lightweight materials also reduce motion inertia, improving safety and energy efficiency.

High-performance characteristics are essential. Robot joints endure high-frequency reciprocating motion, requiring fasteners with extreme fatigue resistance and loosening prevention (e.g., using Nord-Lock washers or special thread-locking coatings). Drones operating outdoors face vibration, temperature variations, and corrosion, demanding excellent corrosion resistance (achieved through treatments like Dakrom or stainless steel material) and vibration resistance from fasteners.

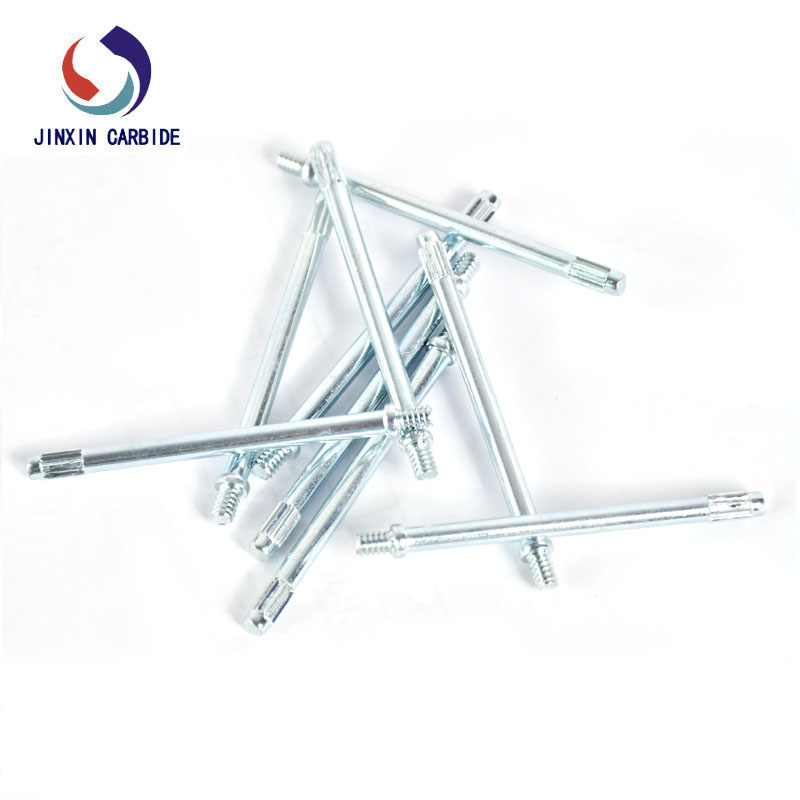

Conclusion: Universal standard parts struggle to meet high-end demands. Customized, high-performance fasteners utilizing new materials and processing technologies are becoming the core driver for industry value addition.